0091 98 967 44 968

dineshvrm@gmail.com

Newsletter

0091 98 967 44 968

dineshvrm@gmail.com

Menu

Categories

- Refurbished

- Home Decor & Art

- Showpieces

- Homekeeping

- Chemistry Lab

- Showpieces

- Pharmacology Lab

- Housekeeping

- Ovens & Incubators

- ICU Beds

- Tableware

- Metallurgical

- Tool Maker's Microscope

- Civil Lab

- Specimen Mounting Press

- Brinell Microscope

- Jominy End Quench

- Specimen Leveller

- Metallurgical Microscopes

- Muffle Furnace

- Spectro Polisher

- Specimen Cutting Machine

- Autocollimator

- Specimen Sets

- Polishing Machine

- Material Pro Software

- Belt Grinder

- Vickers Hardness Tester

- Profile Projector

- Rockwell Hardness Tester

- Microscopes

- Penta Head Microscopes

- Laboratory Microscopes

- Stereo Microscope

- Polarising & ORE Microscopes

- Deca Head Microscope

- INDUSTRIAL MICROSCOPES

- Travelling Microscope

- Dissecting and Student Microscope

- Ultra Series Microscope

- Medical and Research

- Inverted Tissue Culture

- Fluorescence Mcroscope

- Projection Microscope

- Digital Microscope

- Houseware & Room

- Laboratory Glassware

- Fowler Bed

- Vintage Decorative

- Indoor & Outdoor

- SEMI FOWER BED

- Wall Accent

- Indoor Plants

- Plain Bed

- Wall Accents

- Biology Lab

- Lighting & Lamps

- Delivery Beds & Tables

- Physics Lab

- Lighting & Lamps

- Laboratory

- Mattress & Accent

- Softwares

- Mattress Topper

- MICROPHOTOGRAPHY

Wishlist

Please, install YITH Wishlist plugin

Automatic CO2 Incubator Air Jacketed

Features:

- Automatic CO2 Incubator Air Jacketed

- Designed for tissue culture application and ideal for agricultural field

- Solid state electronic temperature controller having dual display for set and process temperature

- Highly accurate co2 level controller have both digital display for set and process co2 level

- Interior of 304 type stainless steel and exterior made of G.I duly finished in epoxy powder coated shade

- Air jacketed design assure excellent uniformity

Bacteriological Incubator

In biology, an Incubator is a device used to grow and maintain microbiological cultures or cell cultures. The incubator maintains optimal temperature, humidity and other conditions such as the carbon dioxide (CO2) and oxygen content of the atmosphere inside. Incubators are essential for a lot of experimental work in cell biology, microbiology and molecular biology and are used to culture both bacterial as well as Eukaryotic cells.

Blood Bank Incubator

- Blood Bank Incubator (Cabinet)

- Designed for easy and safe storage of blood, vaccines, regents and cultures

- Double walled interior stainless steel and exterior of G.I sheet finished with epoxy powder coated shade

- Cabinet is highly insulated between the walls minimize the heat exchange and energy loss.

- Digital temperature display, resolution to within 0.1c solid state electronic temp. controller

- Inner made of 316L S.S and exterior S.S 304 matt finish in GMP Model

BOD Incubator

A BOD incubator is an incubator designed to maintain 20 °C necessary to perform a test called Biochemical Oxygen Demand (BOD). It involves incubating samples saturated with oxygen at 20 °C for (usually) five days. Such an incubator has a compressor to depress the temperature below ambient and a heater to bring it back up to 20 °C. These work against each other and produce very precise temperature control, often as close as +/-0.1 °C.

Double Walled Incubator

Features:

- Double Walled Incubator C GMP Series

- Double walled in construction with inner made of 316L mirror finish & exterior made of 304 S.S matt finish

- High grade wool/PUFF insulation between the wall to minimize the heat exchange

- Choice to select solid state DIGITAL temp. Controller or microprocessor based PID temp. Controller with centronic port for printer output or without centronic port

- Air circulation being performed by motorized blower firmly install at the bottom of the unit

Dual Incubators

Coming in durable double walled construction support, these advanced technology based Dual Incubators come with thick PUF insulation that allows optimum temperature stability as well as also ensure comparatively reduced consumption of energy.

Specifications:

- Material: Stainless Steel

- Dimension: 340×325×340 mm

- Electric Power: 220 V/50 Hz

Hot Air Oven

Hot Air Ovens are electrical devices used in sterilization. Generally, they can be operated from 50 to 300 DegreeC (122 to 572 DegreeF) . There is a thermostat controlling the temperature. These are digitally controlled to maintain the temperature.

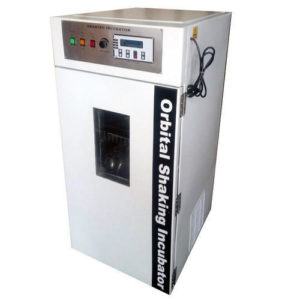

Orbital Shaking Incubator

In an Orbital shaker incubator the unit is added with a typical shaker that has a table board that oscillates horizontally, powered by an electric motor. The liquids to be stirred are held in beakers, jars, or Erlenmeyer that are placed over the table; or, sometimes, in test tubes or vials that are nested into holes in the plate. Orbital shakers also exist, that shake the vessel in a circular fashion.

Tray Dryer

Drying is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semi-solid or liquid. This process is often used as a final production step before selling or packaging products. To be considered "dried", the final product must be solid, in the form of a continuous sheet (e.g., paper), long pieces (e.g., wood), particles (e.g., cereal grains or corn flakes) or powder (e.g., sand, salt, washing powder, milk powder). A source of heat and an agent to remove the vapor produced by the process are often involved. In bio-products like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water.

Universal Oven (Memmert type)

Universal Oven (Memmert type) : Standard double walled construction. Inner chamber made of aluminum or stainless steel sheet. Exterior made of mild steel sheet finished in powder coated color combinations. Three sides heating provides uniform and quick temperature rise in range of 50°C to 250°C ± 2°C and is thermostatically controlled.

Vacuum Oven

A Vacuum Oven is a type of oven that can heat materials, typically metals, to very high temperatures and carry out processes such as brazing, sintering and heat treatment with high consistency and low contamination.

In a vacuum oven the product in the oven is surrounded by a vacuum. The absence of air or other gases prevents heat transfer with the product through convection and removes a source of contamination.

Categories

- Biology Lab

- Chemistry Lab

- Delivery Beds & Tables

- Fowler Bed

- Home Decor & Art

- Homekeeping

- Housekeeping

- Houseware & Room

- ICU Beds

- Indoor & Outdoor

- Indoor Plants

- Laboratory

- Laboratory Glassware

- Lighting & Lamps

- Lighting & Lamps

- Mattress & Accent

- Mattress Topper

- Metallurgical

- Autocollimator

- Belt Grinder

- Brinell Microscope

- Civil Lab

- Jominy End Quench

- Material Pro Software

- Metallurgical Microscopes

- Muffle Furnace

- Polishing Machine

- Profile Projector

- Rockwell Hardness Tester

- Specimen Cutting Machine

- Specimen Leveller

- Specimen Mounting Press

- Specimen Sets

- Spectro Polisher

- Tool Maker's Microscope

- Vickers Hardness Tester

- MICROPHOTOGRAPHY

- Microscopes

- Deca Head Microscope

- Digital Microscope

- Dissecting and Student Microscope

- Fluorescence Mcroscope

- INDUSTRIAL MICROSCOPES

- Inverted Tissue Culture

- Laboratory Microscopes

- Medical and Research

- Penta Head Microscopes

- Polarising & ORE Microscopes

- Projection Microscope

- Stereo Microscope

- Travelling Microscope

- Ultra Series Microscope

- Ovens & Incubators

- Pharmacology Lab

- Physics Lab

- Plain Bed

- Refurbished

- SEMI FOWER BED

- Showpieces

- Showpieces

- Softwares

- Tableware

- Uncategorized

- Vintage Decorative

- Wall Accent

- Wall Accents

Product Status

Example Title

Door sit amet, consectetur adip iscing elit, sed do ore magna lorem ipsum sit.

MORE

You may like it

More

More