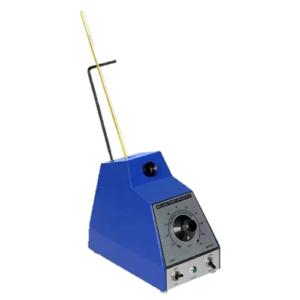

ROTARY EVAPORATOR

MAKE DINESH SCIENTIFIC

DESCRIPTION

The best foundation for effective evaporation in your laboratory is a rotary evaporator. They work well for automated distillation, complicated distillation procedures, and ordinary distillation. The evaporators have been developed with careful consideration for factors including cost-effectiveness, convenience, and safety. Several distinct product advantages show this. All evaporators, among other things, include a separate ON/OFF switch for the heating feature. Easy Lift, a straightforward touch motion to raise the flask, is also included. You can also create your own customized modular concept with the rotary evaporators, which include the rotary evaporator, vacuum controller, vacuum pump, and chiller. Evaporator: a dependable way to distill your solvents. Provides a clever way to handle your solvent.

PERFORMANCE FEATURES:

- Includes a built-in combo-clip.

- Featuring an LED rotation speed adjustment.

- Has a flexible bath position.

- Includes an electrical rotation drive with speed control.

- Featuring an easily removable vapor tube for easy cleaning.

- Has a safety protective switch to prevent overheating.

- Sealing Ring (Vacuum Seal): Graphite filled PTFE

- SS316 heating bath.

- Lift kind that operates automatically.

- Featuring a secondary safety cutoff switch.

WATER OR OIL BATH:

- A hot water or oil bath is partially submerged in the flask. The heat required for the solvent in the sample to evaporate is provided by the bath.

ROTARY MOTOR:

- The entire flask assembly is rotated by a motor, causing the sample to spread into a thin film along the inner surface of the flask. This increases the surface area for efficient evaporation.

VACUUM SYSTEM:

- By lowering the system’s pressure via a vacuum system, the solvent’s boiling point is lowered and the evaporation process is facilitated. Moreover, it aids in keeping the sample from overheating.

CONDENSER:

- In the condenser, the sample’s vaporized solvent is subsequently condensed back into liquid form. Usually, cold water or another cooling liquid is circulated to cool the condenser.

FEATURES:

- Built-in vacuum controller

- Low Noise

- Chemical Resistance

- Overheating protection

- Compatible with all range of glassware

- Highly resistant and particularly durable PTFE vacuum seals

- The flashing and the residual heat display alert people to the possibility of burns over 500C

- Smooth Start.

TECHNICAL DETAILS:

| MODEL | DS-RE-4 |

| Motor Drive | DC brushless motor with speed range of 20-280 rpm |

| Cooling Surface Area | 1500 cm² or larger for better recovery rate |

| Motorised Lift | Equipped with safety stop function |

| Bath Capacity | 4 litres |

| Heating Temperature Range | Room Temperature (RT) to 170°C |

| Heat Control Accuracy | ±1 K |

| Protection Class | IP 20 |

| Safety Features | Dry-run prevention and a safety temperature circuit for the heating bath |

| Rotation | CW & CCW rotation with interval option for faster powder drying |

| Locking Function | Prevents accidental changes to heating bath settings |

| Standalone Heating Bath | Can be used independently for other applications |

| Display and Timer | TFT graphical display for real-time operation progress with a timer function |

| Device Voltage | Low device voltage (24V) ensures user safety |

| Included Components | Digital heating bath, set of glassware (vertical), receiving flask, evaporation flask |

| CHILLER | |

| Warning Signals | Acoustic and optical warnings |

| Bath Volume | 3.5 liters with volume level indicator |

| Temperature Stability | ± 1 K |

| Temperature Control Range | -20°C to 100°C |

| Pump Type | Speed-regulated pump |

| Safety and Maintenance Features | For ease of handling and cleaning, the front has a safety drain and filters. |

| Pump Pressure | Pressure flow: ~0.3 bar, Suction: ~0.2 bar |

| Flow Rate | 15 liters per minute with provision to control flow rate |

| VACUUM PUMP | |

| Vacuum Pump Type | Speed-controlled, four-chamber membrane vacuum pump |

| Material in Contact with Medium | Al₂O₃, PTFE, FFPM, PPS, NBR |

| Speed Adjustment | Speed with digital display of pressure and control |

| Suction Capacity | 1.2-2 m³/h |

| Ultimate Vacuum Level | 2 mBar |

| Housing Material | Alu-cast coating / thermoplastic polymer |

| Boiling Point Detection | Automatic detection of boiling point |

| Noise Level | 55 dB(A) at low pressure |

Reviews

There are no reviews yet.