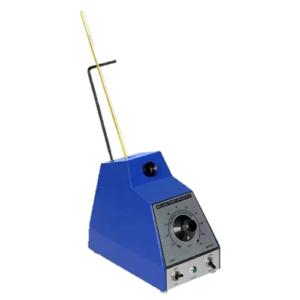

HYDRAULIC HORIZONTAL SURFACE GRINDERS

MAKE DINESH SCIENTIFIC

DESCRIPTION

These grinders have great levels of accuracy and efficiency when it comes to surface grinding activities since they use hydraulic systems to regulate various actions. The following is a summary of the main attributes and parts that are usually present in hydraulic horizontal surface grinders:

BED AND TABLE:

The work piece is positioned on the table and moves back and forth beneath the grinding wheel.

Typically, the machine is made up of a sturdy bed supporting a horizontal table.

GRINDING WHEEL:

A revolving grinding wheel is positioned above the work piece and attached on a spindle.

The wheel removes material off the surface of the work piece to provide a smooth and level finish.

HYDRAULIC SYSTEM:

Different machine parts are moved under the control of hydraulic power.

A hydraulic pump, valves, and cylinders make up the hydraulic system.

The vertical movement of the grinding wheel and the longitudinal and transverse movement of the table are both managed by hydraulic pressure.

VERTICAL FEED:

Hydraulic systems modify the grinding wheel’s vertical position;

The vertical feed regulates the depth of cut or the amount of material removed with each pass of the grinding wheel.

COOLANT SYSTEM:

A coolant system helps maintain constant grinding performance and extends the life of the grinding wheel.

It is a feature of many surface grinders.

It prevents overheating of the work piece and grinding wheel.

SAFETY FEATURES:

- To shield operators from potential risks when operating a machine

- Safety guards and interlocks are installed.

- In the manufacturing

- Tool and die

- Precision engineering sectors

- Where high-precision flat surfaces are crucial to the creation of high-quality components

- Hydraulic horizontal surface grinders are extensively utilized.

TECHNICAL DETAILS:

| MODEL | DS-HSG-M-2800 |

| Transverse moments of wheel head or table | Manual |

| Material Removal rate in gm/ min | 0.1 |

| Length of Guide way in mm | 300 |

| Width of Guide way in mm | 100 |

| Availability of heavily ribbed for better vibration damping and shock absorption | Yes |

| Range of Table Speed in m/min | 5 |

| Precision Three Jaw Self Centering Chucks to hold up to 50 mm jobs | Yes |

| Magnetic base Table, 200 mm X 125 mm with magnetizing & demagnetizing | Yes |

| Weight that can be handled by machine in kg | 50 |

| Vertical feed Graduation in mm | 0.01 |

| Cross feed Graduation in mm | 0.05 |

| Weight of Machine in kg | 350 kg |

| Overall Dimensions of the machine in mm x mm x mm (L x W x H ) | 450X700X1100 mm |

| Type of grinding wheel | SILICON |

| Width of Grinding Wheel in mm | 12 |

| Diameter of Grinding Wheel (OD x ID) | 150 |

| Grinding Wheel Speed in rpm | 2800 rpm |

| Capacity of Grinding Wheel Head Motor in kw | 0.74 |

| Motor Capacity for Pump for Hydraulically operation in kw | 0.74 |

| Speed of motor of pump for Hydraulically operation in rpm | 1440 |

| Capacity of coolant motor in hp | 0.15 |

| Number of T slots on Table | 1 |

| Width of T slots on Table in mm | 8 mm |

| Spacing of T slots in table in mm | 8 mm |

| Width of wheel head guide way in mm | 75 mm |

| Noise level of machine at 1 meter distance in db | 85 db |

| Size of main spindle bearing of machine | 25 |

| Instruction Manuals 3 set | Yes |

| Working Surface Area of the table or Table Clamping area (L x W ) in mm x mm | 150 x 300 mm |

| Height from table to Grinding Wheel in mm | 100 mm |

| Material of Bed | High Tensile Strength Cast Iron |

| Least count of hand wheel for in feed in mm | 0.1 |

| Precision Three Jaw Self Centering Chucks size 100 mm | Yes |

| Hand operated chuck | Yes |

| Availability of Switch for operating electromagnetic chuck | Yes |

| Availability of Handle operated electromagnetic chuck | Yes |

| Coolant equipment with settling tank | Yes |

| Electrical equipment completes with wiring suitable for 415 volts,3 Phase, 50 cycles AC supply | Yes |

| The machine meets with the accuracy of Dr Schlesinger Standard requirement | Yes |

| Availability of Hand tools such as spanners, Screw Drivers, etc | Yes |

| Internal attachment, suitable quills to grind 100 mm deep jobs | Yes |

| Grinding Wheel Balancing stand to balance 300 mm Dia Wheel | Yes |

| Steady Rest | Yes |

| ADITIONAL | |

| Grinding wheel (coarse and fine) | 3 nos |

| Operating mode | Manual |

| Wheel balancing stand | One |

Reviews

There are no reviews yet.