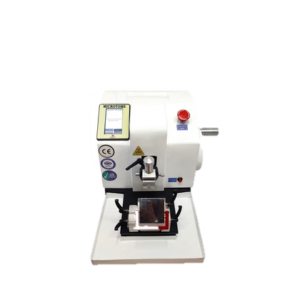

HIGH TEMPERATURE MUFFLE FURNACE

MAKE DINESH SCIENTIFIC MODEL DS-MF-15-1200

PRODUCT DESCRIPTION

We are engaged in providing respected clients an exclusive assortment of Muffle Furnace. The offered product variety is made-up by use of Premium quality of raw material and metals that make it more reliable and able to serve for long. These products are made-up under the guidance of experts in line with industry set norms and standards. Offered products range are available with us at very nominal rates in the market.

SCOPE OF APPLICATION:

They are made from heat-resistant material with high thermal conductivity, which allows it to maintain the desired temperature inside the chamber. The combination of radiant and convection heat transfer provides a homogeneous treatment of the workpieces.

Muffle furnace offers numerous advantages, such as; low proportional energy consumption, more efficient thermal insulation, more uniform heat distribution in the equipment, temperature and process control, high performance and durability heating system, exhaust gases from the process

PRINCIPAL OF MUFFLE FURNACE:

The working principle of a lab muffle furnace which is also known as a retort furnace is to heat the air inside its chamber using the basic fundamentals of thermal convection and thermal radiation.

A Muffle furnace allows rapid high-temperature heating, recovery, and cooling in self-contained, energy-efficient cabinets. A muffle furnace separates the object heated from all byproducts of combustion from the heat source.

MUFFLE FURNACE USESD IN A LABORATORY:

Muffle furnaces isolate the samples from the fuel and the combustion to eliminate contamination of the samples. They are durable, reliable, and work well for extensive use. Muffle furnaces are ideal for research and development, materials testing and quality control, heat treatment, ceramics, glass, and so much more.

TECHNICAL DATA:

| PARAMETER | VALUE |

| Muffle furnace Temperature | 1200°C |

| Chamber size (volume) | 15L usable volume |

| Display | Computer controlled LED / LCD Display |

| Power Input | 230 V ± 10 % Single Phase, 50 Hz AC |

| Heating element | • Excellent AF wire heating element embedded into ceramic plates to protect against fumes and splashing.

• Accessible from all sides of the furnace (except from the front and back). |

| Insulation Material | High-quality fiber insulation in the heating chamber that is not categorized as carcinogenic under TRGS 905, Class 1 or 2. |

| Furnace Housing | • Rust-resistant, textured stainless steel sheets are used to make the housing.

• Housing with two shells designed to withstand temperatures below 60°C outside. |

| Door system | The furnace door (LIFT TYPE) is positioned such that the operator cannot see the hot surface. |

| Air inlet | The top or rear wall of the furnace has an adjustable air input that is connected with the exhaust air opening. |

| Temperature Control | • Ten programs, each with five stages

• Are available on this microprocessor-based PID programmer/digital temperature indicator. |

| LCD display | • There is a program recall option available.

• Touch-sensitive LCD display with program entry capability for five programs and four segments |

| Temperature uniformity | The 15-liter furnace’s temperature uniformity within the isothermal zone was represented graphically at 1200°C, with a variation of ±5°C along each chamber direction. |

| Relay | A solid state relay is included for quiet operation. Program settings: Thyristor power drive unit combined with multi-segment microprocessor-based programmable PID temperature controller for ramp/dwell control. |

| Thermocouple | • Form S, The temperature of the furnace chamber is controlled and monitored by a long-life thermocouple (NiCrSi-NiSi Tmax <(> <<)>).

• PtRh-Pt Tmax > 1200 °C or 1200 °C) |

| Furnace lining | The hot face grooved refractory is used to fix the heating element and is supported by low thermal mass insulation. |

| Ceramic base | • Such as ceramic fiber board, to reduce body temperature below 60°C during and after soaking.

• There is one suitable ceramic base offered for the inner chamber base. |

| Over temperature protection controller | Provide over protection controller with variable set temperature |

| Temperature Accuracy | ± 1°C |

| Temperature | 100 to 1200°C, Continuous operation at 1100°C |

| Heating Rate | The furnace slow & fast heating type (1-10°C/min). |

| Power | 15 litters of chamber capacity with 3.5 kW of peak power and a single phase input. |

| Dimension | Inner dimensions of 230 mm W x 340 mm D x 170 mm H and outside dimensions of 415 mm W x 555 mm D x (515+240) mm H correspond to the protection class furnace. |

| Heating rate | Operating temperature for a 15-liter chamber reached in 100 minutes. |

| Software | • Software for documentation, control, and visualization is included with the furnace.

• Software that can be used to store 400 distinct heat treatment regimens and process data can be recorded. |

| PC | • The PC’s software was used to start and stop the controllers.

• In accordance with this, the procedure is recorded and preserved • The data display implemented as a table or in a diagram. |

| Windows | • It’s even feasible to generate reports in PDF format or move process data to Excel TM for MS Windows TM (.csv format ).

• Applications Fit for Operating Systems The furnace is supplied with a suitable laptop running Microsoft Windows 7/8/10/1. |

| Processor | Intel Core i5-1035G1, 10th Generation, 1.0 GHz Base, 6MB Cache, 3.6 GHz Turbo Speed, 4 Cores. |

| Memory | 8GB (4GB onboard + 4GB SO-DIMM) DDR4 |

| Storage | 512GB M.2 NVMe PCIe 3.0 SSD, with one 2.5-inch HDD storage slot empty. |

| Display | 14.0-inch (35.56 cm) |

| windows | Operating system windows 11 |

| Below listed items provided along with the furnace as standard

|

• Over Temperature Limiter -2 Nos

• Heating Element /Plate -2 Nos • Software with Ethernet connection • Latest Laptop /PC Suitable for the furnace and software |

| Over temperature protection has provided in the furnace | Yes |

| The temperature on the outer wall of the casing not exceed 60°C | Yes |

Reviews

There are no reviews yet.