BLOW FILM PLANT EXTRUSION

Make Dinesh Scientific

DESCRIPTION

The extrusion technique is widely used in the film industry to create plastic sheets, films, and other products that have the required qualities and a constant thickness. In the context of making movies, the extrusion process is briefly described as follows:

PREPARING THE RAW MATERIALS:

The first step in the process is to prepare the raw materials, which are usually polymers or plastic resins that are melted to create a molten mass.

EXTRUSION DEVICE:

- After that, the molten material is fed into an extrusion apparatus. This device is made up of one or more screws housed inside a barrel. Melting material is forced through the barrel by the rotating screw or screws.

DIE DESIGN:

- The molten material is passed through a specially made die during the extrusion process, which controls the film’s thickness and shape. The die in film production is often a flat aperture in the shape of a slit.

SIZING AND COOLING:

- The material is quickly cooled after going through the die to form a film. There are several ways to accomplish this, including water cooling and air cooling.

TAKING-UP FRAMEWORK:

- A take-up system is then used to pull or roll the newly created film away from the extrusion machine. The produced film will have a constant pace and level of suspense thanks to this approach.

TWISTING AND SLICING:

- Lastly, depending on the intended use, the film may be cut into predetermined lengths or wound onto rolls.

COOLING AND SIZING:

- After passing through the die, the material is rapidly cooled to solidify it into a film. This can be done using various methods such as air cooling or water cooling.

TECHNICAL DETAILS:

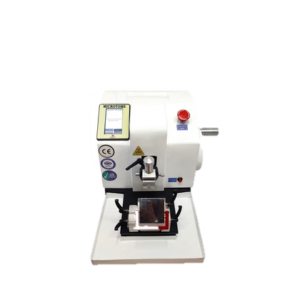

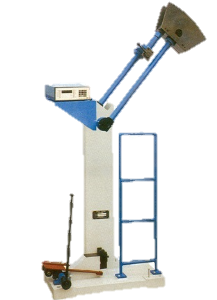

| MODEL | DS-BFP – 100 |

| Panel | Compact Panel Attached to the Machine |

| Design | Special Compact Design for Lab Purpose Blown Film Plant |

| Blown Film Dies | Blown Film Dies |

| Controls | PID Controls and Variable Drives |

| Extruder | 25 MM Extruder with L.D/L.L. and H.M/LL. |

| Design | Special Compact Design for Lab Purpose Blown Film Plant |

| Machine Status | Ready to Use |

| Installation Requirements | Need Only to Plug In |

Reviews

There are no reviews yet.