0091 98 967 44 968

dineshvrm@gmail.com

Newsletter

0091 98 967 44 968

dineshvrm@gmail.com

Menu

Categories

- Refurbished

- Home Decor & Art

- Showpieces

- Homekeeping

- Chemistry Lab

- Showpieces

- Pharmacology Lab

- Housekeeping

- Ovens & Incubators

- ICU Beds

- Tableware

- Metallurgical

- Tool Maker's Microscope

- Civil Lab

- Specimen Mounting Press

- Brinell Microscope

- Jominy End Quench

- Specimen Leveller

- Metallurgical Microscopes

- Muffle Furnace

- Spectro Polisher

- Specimen Cutting Machine

- Autocollimator

- Specimen Sets

- Polishing Machine

- Material Pro Software

- Belt Grinder

- Vickers Hardness Tester

- Profile Projector

- Rockwell Hardness Tester

- Microscopes

- Penta Head Microscopes

- Laboratory Microscopes

- Stereo Microscope

- Polarising & ORE Microscopes

- Deca Head Microscope

- INDUSTRIAL MICROSCOPES

- Travelling Microscope

- Dissecting and Student Microscope

- Ultra Series Microscope

- Medical and Research

- Inverted Tissue Culture

- Fluorescence Mcroscope

- Projection Microscope

- Digital Microscope

- Houseware & Room

- Laboratory Glassware

- Fowler Bed

- Vintage Decorative

- Indoor & Outdoor

- SEMI FOWER BED

- Wall Accent

- Indoor Plants

- Plain Bed

- Wall Accents

- Biology Lab

- Lighting & Lamps

- Delivery Beds & Tables

- Physics Lab

- Lighting & Lamps

- Laboratory

- Mattress & Accent

- Softwares

- Mattress Topper

- MICROPHOTOGRAPHY

Wishlist

Please, install YITH Wishlist plugin

Sonometer Wooden

Comprising a hollow wooden resonance box, with two meter rules graduated in millimetres, mounted on top on either side along the length.

One each of brass and steel wires of different diameter attached to fixed bridge on one end of the box and tensioned by wrest pins at the other end.

A pulley mounted at the end supports third wire over it with masses suspended to the wire end. Includes two short and two long bridges for adjusting length of vibrating strings, and additional wires one each of steel and brass of 22SWG.

Sonometer Wooden

Comprising a hollow wooden resonance box, with two meter rules graduated in millimetres, mounted on top on either side along the length.

One each of brass and steel wires of different diameter attached to fixed bridge on one end of the box and tensioned by wrest pins at the other end.

A pulley mounted at the end supports third wire over it with masses suspended to the wire end. Includes two short and two long bridges for adjusting length of vibrating strings, and additional wires one each of steel and brass of 22SWG.

Stethoscope

Highly sensitive, good quality with rubber tubing, useful for observing faint sounds and vibrations after due amplification

Stethoscope

Highly sensitive, good quality with rubber tubing, useful for observing faint sounds and vibrations after due amplification

Stroboscope Digital

100-10,000 RPM/flash per min.

Accuracy: +/- (.05% +1d).

Stroboscope Digital

100-10,000 RPM/flash per min.

Accuracy: +/- (.05% +1d).

Stroboscope Hand

Slotted metal disc, with finger hole and having 12 radial slots, mounted on a handle.

Stroboscope Hand

Slotted metal disc, with finger hole and having 12 radial slots, mounted on a handle.

Tuning Fork Electrical

Mounted on sturdy streamlined base with provision for horizontal or vertical use, fork is manufactured from selected steel. Prong is 10 x 25 x 300 mm. accurate frequency adjustment, vibrations rate 60 per second. Electromagnet can work on 6 Volts. The amplitude of vibration can vary by sliding the electromagnet inside the prongs.

Tuning Fork Electrical

Mounted on sturdy streamlined base with provision for horizontal or vertical use, fork is manufactured from selected steel. Prong is 10 x 25 x 300 mm. accurate frequency adjustment, vibrations rate 60 per second. Electromagnet can work on 6 Volts. The amplitude of vibration can vary by sliding the electromagnet inside the prongs.

Tuning Fork Electrically Maintained (Melde’s Apparatus)

On sturdy streamlined base with provision for horizontal or vertical use. Forks is manufactured from selected steel. Prong is 10 x 25 x 300 mm. accurate frequency adjustment, chrome plated, vibrations rate 60 per seconds. Electromagnet can work on 6 volts. The amplitude of vibration can vary by sliding there electromagnet inside prongs. Complete with bench clamp, pulley, and scale pan.

Tuning Fork Electrically Maintained (Melde’s Apparatus)

On sturdy streamlined base with provision for horizontal or vertical use. Forks is manufactured from selected steel. Prong is 10 x 25 x 300 mm. accurate frequency adjustment, chrome plated, vibrations rate 60 per seconds. Electromagnet can work on 6 volts. The amplitude of vibration can vary by sliding there electromagnet inside prongs. Complete with bench clamp, pulley, and scale pan.

Tuning Fork Hammer

A rubber ring mounted on a metal disc with steel rod and wooden handle

Tuning Fork Hammer

A rubber ring mounted on a metal disc with steel rod and wooden handle

Tuning Fork Pair on box (Beats Apparatus)

It comprises two tuning forks each of frequency 426 Hz on two separate resonance boxes. One fork is fitted with adjustable loading mass. When both forks are sounded together, a clearly audible beat is produced. Rate of beats depends on difference in frequencies. This difference can be increased by changing the loading mass.

Tuning Fork Pair on box (Beats Apparatus)

It comprises two tuning forks each of frequency 426 Hz on two separate resonance boxes. One fork is fitted with adjustable loading mass. When both forks are sounded together, a clearly audible beat is produced. Rate of beats depends on difference in frequencies. This difference can be increased by changing the loading mass.

Tuning Forks on Resonance Box

Three Tuning forks are mounted on three wooden resonance boxes dimensions of which are compatible with frequency of the forks to produce a strong sustained tone. Forks are nickel plated with shanks to screw in the bushes on the top of the boxes. Each set supplied with rubber headed hammer.

Tuning Forks on Resonance Box

Three Tuning forks are mounted on three wooden resonance boxes dimensions of which are compatible with frequency of the forks to produce a strong sustained tone. Forks are nickel plated with shanks to screw in the bushes on the top of the boxes. Each set supplied with rubber headed hammer.

Tuning Forks Set of 13

Nickel-plated steel, plain shanks, with frequency marked from C (256) to C (512). Complete set of 13 Tuning Forks supplied in case.

Tuning Forks Set of 13

Nickel-plated steel, plain shanks, with frequency marked from C (256) to C (512). Complete set of 13 Tuning Forks supplied in case.

Tuning Forks Set of 13 Aluminium

Plain shanks, aluminium made, with frequency marked from C (256) to C (512). Complete set of 13 Tuning Forks supplied in case.

Tuning Forks Set of 13 Aluminium

Plain shanks, aluminium made, with frequency marked from C (256) to C (512). Complete set of 13 Tuning Forks supplied in case.

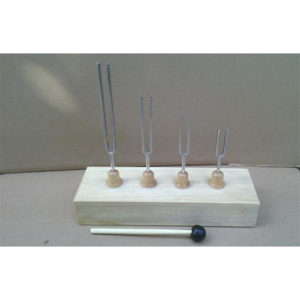

Tuning Forks Set of 4

Four tuning forks are mounted on a single proper sized resonance box to produce a major chord. Forks have frequencies of C1 256, E 320 Hz, G 384 Hz and C2 512 Hz. When struck together with hammer, the forks will produce the chord of C major, supplied with one hammer.

Tuning Forks Set of 4

Four tuning forks are mounted on a single proper sized resonance box to produce a major chord. Forks have frequencies of C1 256, E 320 Hz, G 384 Hz and C2 512 Hz. When struck together with hammer, the forks will produce the chord of C major, supplied with one hammer.

Tuning Forks Set of 8

Nickel-plated, plain shanks, with frequency marked, C (256), D (288), E (320), F (341), G (384), A (426), B (480), C (512). Complete set of EIGHT tuning forks, supplied in case.

Tuning Forks Set of 8

Nickel-plated, plain shanks, with frequency marked, C (256), D (288), E (320), F (341), G (384), A (426), B (480), C (512). Complete set of EIGHT tuning forks, supplied in case.

Vibrator Electrical (Melde’s Apparatus)

This apparatus is an improvement over the conventional apparatus to show the effects of vibrations in a stretched cord and examine the relationship between frequency, tension and density. A thin steel rod is clamped near one end through two 4 mm socket terminals. This rod passes through the centre of a small solenoid and between the poles of a magnet. Adjustable contact points fitted through a second pair of 4 mm socket terminals make alternating connection with an adjustable contact on the rod. The rod has a small hole at one end for the attachment of thread which passes over a pulley mounted on a bench clamp and supports a scale pan, 75 mm diameter, supplied complete with pulley with clamp and scale pan, 2V A.C. power supply.

Vibrator Electrical (Melde’s Apparatus)

This apparatus is an improvement over the conventional apparatus to show the effects of vibrations in a stretched cord and examine the relationship between frequency, tension and density. A thin steel rod is clamped near one end through two 4 mm socket terminals. This rod passes through the centre of a small solenoid and between the poles of a magnet. Adjustable contact points fitted through a second pair of 4 mm socket terminals make alternating connection with an adjustable contact on the rod. The rod has a small hole at one end for the attachment of thread which passes over a pulley mounted on a bench clamp and supports a scale pan, 75 mm diameter, supplied complete with pulley with clamp and scale pan, 2V A.C. power supply.

Wave from Helix

For demonstration of wave motion, pulses, reflection and interference, steel wire close wound helix, 19 mm diameter closed length 3 meters extending to approximately 9 meters

Wave from Helix

For demonstration of wave motion, pulses, reflection and interference, steel wire close wound helix, 19 mm diameter closed length 3 meters extending to approximately 9 meters

Categories

- Biology Lab

- Chemistry Lab

- Delivery Beds & Tables

- Fowler Bed

- Home Decor & Art

- Homekeeping

- Housekeeping

- Houseware & Room

- ICU Beds

- Indoor & Outdoor

- Indoor Plants

- Laboratory

- Laboratory Glassware

- Lighting & Lamps

- Lighting & Lamps

- Mattress & Accent

- Mattress Topper

- Metallurgical

- Autocollimator

- Belt Grinder

- Brinell Microscope

- Civil Lab

- Jominy End Quench

- Material Pro Software

- Metallurgical Microscopes

- Muffle Furnace

- Polishing Machine

- Profile Projector

- Rockwell Hardness Tester

- Specimen Cutting Machine

- Specimen Leveller

- Specimen Mounting Press

- Specimen Sets

- Spectro Polisher

- Tool Maker's Microscope

- Vickers Hardness Tester

- MICROPHOTOGRAPHY

- Microscopes

- Deca Head Microscope

- Digital Microscope

- Dissecting and Student Microscope

- Fluorescence Mcroscope

- INDUSTRIAL MICROSCOPES

- Inverted Tissue Culture

- Laboratory Microscopes

- Medical and Research

- Penta Head Microscopes

- Polarising & ORE Microscopes

- Projection Microscope

- Stereo Microscope

- Travelling Microscope

- Ultra Series Microscope

- Ovens & Incubators

- Pharmacology Lab

- Physics Lab

- Plain Bed

- Refurbished

- SEMI FOWER BED

- Showpieces

- Showpieces

- Softwares

- Tableware

- Uncategorized

- Vintage Decorative

- Wall Accent

- Wall Accents

Product Status

Example Title

Door sit amet, consectetur adip iscing elit, sed do ore magna lorem ipsum sit.

MORE

You may like it

More

More