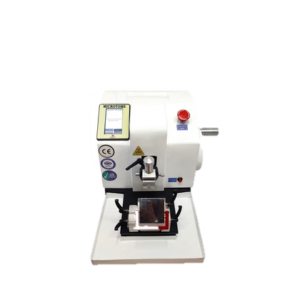

ROTARY MICROTOME

MAKE DINESH SCIENTIFIC

MODEL DS-RM-100

DESCRIPTION:

PRECISION CUTTING:

Allows for extremely thin and precise sections of specimens cut, essential for microscopic examination.

The rotary microtome rotates on a rotary principle, moving the specimen in small increments in the direction of a sharp blade. The tissue is sectioned smoothly and continuously thanks to this rotational movement. Because the sections’ thickness precisely changed, pathologists and researchers can get slices with different thicknesses to suit their unique experimental or diagnostic requirements.

ADJUSTABLE THICKNESS SETTINGS:

Enables users to select the desired thickness of the slices, typically ranging from 10 to 50 micrometers.

BLADE TYPES:

Compatible with steel, glass, or diamond blades, depending on the specimen type and required slice thickness.

SPECIMEN HOLDER:

Securely holds the specimen in place during the cutting process, ensuring consistent and accurate sections.

OPERATION MODES:

Available in manual, semi-automatic, and fully automatic models to suit different user needs and preferences.

SAFETY FEATURES:

Includes safety mechanisms to protect users from accidental cuts and injuries.

DIGITAL DISPLAY:

Modern microtomes may feature digital interfaces for easy adjustment and monitoring of settings.

Motorized Controls Some models offer motorized advance and retraction of the specimen for enhanced precision and ease of use.

TECHNICAL DETAILS:

MODEL DS-RM-100

Micrometer Feed System Micrometer feed powered by a precise step motor that is backlash-free and requires little upkeep

Movement Mechanisms Cross-roller bearing-based design ensures precise horizontal feed and vertical stroke motion

Hand-Wheel Operation Rocking movement and full rotation for traditional sectioning are the two manual sectioning methods supported by the ergonomic hand-wheel.

Hand-Wheel Locking Featuring two separate locking mechanisms for increased operational security

Force Balancing System Innovative, operator-adjustable force balancing mechanism offering enhanced functionality

Adaptability Permits accurate spring tension adjustment to accommodate different specimen or clamp weights, so avoiding the object head from suddenly falling onto the blade.

Counterbalance Elimination Removes the need for a heavy hand-wheel counterweight, improving user comfort and overall handling

Section Thickness Settings Independent trimming and sectioning thickness settings that individually selected and saved

Control Panel A user-friendly control panel with adjustable tilt for the best ergonomic use incorporates all of the main settings.

Section Thickness Settings Independent trimming and sectioning thickness settings that individually selected and saved

Programmable Specimen Retraction Retraction system with programmable settings and ON/OFF functionality for user flexibility

Front Display Indicators Key operational parameters are clearly displayed on the front panel of the instrument, including:

Trimming/Section Thickness Displays the currently set trimming or sectioning thickness

Specimen Retraction (Retract) Indicates the status of the automatic specimen retraction function

Locking Function (Lock) Shows the status of the hand-wheel or specimen head locking mechanism

Section Counter & Totalizer Tracks the number of sections cut and cumulative thickness; includes a reset function for both

Motorized Horizontal Specimen Movement Enables automated horizontal movement of the specimen head using two user-friendly methods:

Control Panel Operation The control panel’s coarse feed buttons, which used in step feeding or continuous feeding mode, enable movement at two adjustable speeds in each direction.

Ergonomic Coarse Feed Wheel Uniquely designed coarse feed wheel positioned for comfort; user personalize the turn direction to either clockwise or anti-clockwise for intuitive operation

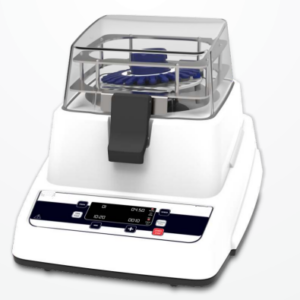

Rocking Mode Function Control panel includes a unique rocking mode designed for efficient trimming operations

Bidirectional Hand-Wheel Detection Permits brief hand-wheel motions back and forth without impairing retraction; every change in rotation direction is electronically sensed and converted into regulated specimen movement.

Sectioning Efficiency Maintains consistent ribboning of sections, even during rocking mode operation

Top Surface Area Large, flat top surface designed for securely placing items and tools during sectioning

Feed and Travel Limit Indicators Visual and audible signals to indicate the remaining feed and the front/rear travel limits of the specimen head

Efficient Specimen Exchange Facilitates quick specimen exchange through a user-programmable Memo position and a fast-homing feature that returns the object head to the rear position within 13±2 seconds

Specimen Orientation Offers precise horizontal and vertical rotation of ±8° with calibrated controls, aided by two red indicators for accurate repositioning of specimens for re-cuts

Optional Removable Tray A detachable top tray provides convenient storage for sectioning tools while preventing items from falling

Section Waste Tray A spacious, antistatic waste tray positioned around the microtome base plate, holding a large volume of waste and reducing cleaning time by 70%

Lateral Blade Displacement Allows lateral adjustment of the blade holder with three predefined stop positions (left, center, right) to match standard cassette widths, ensuring full use of the blade’s length

Quick Clamping System Quick-release clamping system for fast and easy removal or exchange of specimen clamps, optimizing workflow and maintenance

Universal Cassette Clamp Holds cassettes securely in both horizontal and vertical orientations, supporting cassettes with dimensions between 39.8 × 28 mm and 40.9 × 28 mm

Two-in-One Blade Holder A versatile blade holder designed for both high and low-profile blades, featuring a colored safety guard and a safe blade ejection mechanism

Trimming Thickness Range Trimming thickness from 1.0 µm to 600 µm for a wide range of sectioning applications

Section Thickness Setting Range 0.5 to 100 µm

From 0.5 to 5.0 µm 0.5 µm increments

From 5 to 20.0 µm 1.0 µm increments

From 20 to 60.0 µm 5.0 µm increments

From 60 to 100.0 µm 10.0 µm increments

SETTING VALUES (SECTION THICKNESS)

From 1 to 10 µm 1.0 µm increments

From 10 to 20 µm 2.0 µm increments

From 20 to 50 µm 5.0 µm increments

From 50 to 100 µm 10.0 µm increments

From 100 to 600 µm 50.0 µm increments

Lateral Coarse Feed Electronic coarse feed system with user-selectable rotation direction for improved ergonomics

Horizontal Feed Range 24 ±1 mm (0.94 inches), controlled by a step motor for precise feed motion

Vertical Stroke Length 70 ±1 mm, providing precise specimen movement

Specimen Retraction (Manual Mode) Adjustable between 5 and 100 µm in 5 µm increments, with the option to switch ON/OFF at any time

Specimen Retraction (Motorized Mode) Automatically adjusts speed based on sectioning, fully configurable to align with user-specific research needs, with optional upgradeable components

Reviews

There are no reviews yet.