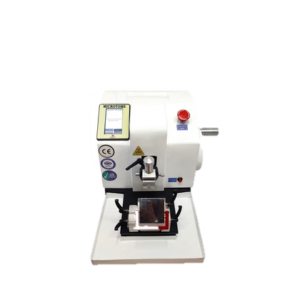

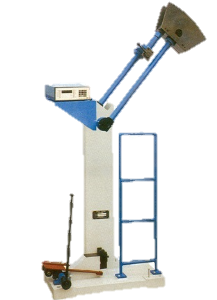

DIGITAL MODIFIED MARSHALL APPARATUS, 50 KN FOR 6″ DIA SAMPLE

DINESH SCIENTIFIC MODEL DS-303

DESCRIPTION:

The is a Digital Modified Marshall Apparatus designed for testing the stability and compaction of paving mix samples. It is widely used in highway departments, construction firms, engineering institutions, testing laboratories, and government agencies. This apparatus measures the resistance to plastic flow of cylindrical specimens of bituminous paving mixtures when subjected to lateral surface loading. The machine is suitable for hot mix applications containing asphalt or tar with aggregates 25.4 mm in size. Its robust design ensures precision and durability for consistent and accurate testing.

Paving Mix Tests, Marshall Stability and Compaction

The most frequently used test by highway departments, contractors, engineers, testing laboratories, and governmental agencies is the stability test using the Marshall Apparatus. The test is intended for the measurement of the resistance to plastic flow of cylindrical specimens of bituminous paving mixture loaded on the lateral surface. It is used with hot mixtures containing asphalt or tar and aggregates 25.4 mm size.

Power: Suitable for operation on 220V, 50 Hz, single phase, AC supply.

SALIENT FEATURES:

Single Speed, Bench-top load frame

Loading capacity: 50 kN

Geared Screw Jack and Motor Drive

Precise speed control

Limit Switch Protection for both upward and downward travel

User-friendly and easy-to-use controls: A thermal overload-type Power Switch at the rear of the machine provides electrical protection. Platen movement is controlled from the front panel by an up-down rotary switch. An emergency switch is provided to stop the machine manually if required. A ball-seated screw fitting located on the crosshead accepts load cells and load transducers up to and including 50 kN.

The equipment is a table-top loading frame, with an crosshead mounted on columns attached to a sturdy base. The forces applied are generated by a screw jack via a reduction unit with worm gears housed in the base casting. Motive power is from an electric motor via a multi-vee drive belt and provides a platen speed of 50.8mm/min. The worm reduction unit is grease-packed on assembly and should not normally require lubrication.

SPECIFICATIONS:

Maximum Vertical Clearance: 470mm

Minimum Vertical Clearance: 250mm

Horizontal Clearance: 265mm

Platen Diameter: 133mm

Platen Travel: 30mm

Platen Speed: 50.8mm/min

Rated Power: 375W

Dimensions (L x W x H): 550 x 400 x 870mm

Weight: 60kg

Reviews

There are no reviews yet.