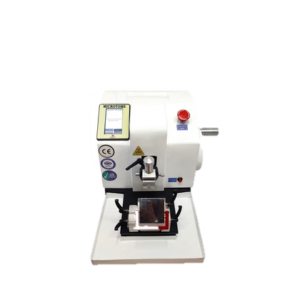

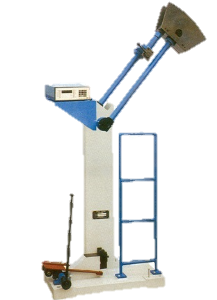

COMPRESSION TESTING MACHINE

MAKE: DINESH SCIENTIFIC MODEL: DS-301

DESCRIPTION:

Experience the epitome of precision and control with the servo-controlled compression testing machine. Operated by an intelligent pace rate controller, this machine offers a host of features to streamline your testing process and ensure accurate results.

KEY FEATURES:

CONTROLLER:

Intelligent Controller enables automatic pace rate control, data logging, data printing, and load hold functionalities, ensuring consistent and reliable testing parameters.

Advanced Control Features:

Automatically controls the pump, adjusts pace rates, and initiates shutdown under predetermined conditions, optimizing workflow and minimizing manual intervention.

PID FEEDBACK CONTROL:

Full three-term PID feedback control using servo motors and driver sets maintains precise pace rates for accurate and repeatable testing.

SILENT HYDRAULIC PUMP

Features a silent hydraulic pump, providing a quieter work environment without compromising performance.

SYSTEM DESCRIPTION

LOADING UNIT:

Features an oil-filled ball socket, piston, and cylinder assembly for precise force transmission and uniform force distribution across test specimens.

Compression parameters allow customization according to specific testing standards. Safety mechanisms, including over-travel protection, prioritize operator safety and prevent equipment damage.

SERVO MOTOR OPERATED HYDRAULIC PUMP:

Provides precise and dynamic force control, combining servo motor accuracy with hydraulic system power. Enables real-time hydraulic pressure adjustments, ensuring repeatable results and accommodating complex testing requirements. Features overload protection and emergency stop functionalities.

ELECTRONIC CONTROLLER WITH TOUCH DISPLAY

Touch-screen EDI with integral load pacing bar display, live pace rate display, load & stress result display, USB output, and Wi-Fi capability. Stores 2000 test results, available in Imperial/English, Metric, or SI units, downloadable via USB.

PRECISION PLATENS:

Hardened, ground, and polished platens with self-aligning action and suitably sized spacers accommodate various specimen sizes.

ADDITIONAL FEATURES:

Heavier frame for increased stiffness and improved aesthetics

Servo motor-powered pump for daylight closure

Noiseless operation

Oil-filled ball seating with heavy-duty upper platen for stability

High degree of control throughout the testing process

Door-closed safety feature

Over piston travel protection

10.1-inch TFT LED backlit display, Resolution: 800×480 (RGB)

Unique storage options: internal memory, USB, and Wi-Fi-based cloud storage

Real-time display of load Vs. time graph

Wi-Fi enabled for data transfer and standalone operation (optional)

Automatic pace rate control and stress determination

Overload safety protection

Configurable engineering unit selection

TECHNICAL SPECIFICATIONS:

Type: Microcontroller-Based Compression Testing Machine, Servo-Controlled

Capacity of 2000 kN, ensuring robust testing performance.

Measurement range of 2000 with a resolution of 0.1 kN for precise readings.

Clearance between platens is 380 mm, providing ample space for various specimen sizes.

Distance between side plates is 360 mm, ensuring structural stability.

Upper platen size of 300 mm (round) and lower platen size of 200 mm (square) for diverse testing needs.

piston diameter of 222.2 mm and piston stroke of 50 mm for efficient load application.

Compatible with specimen sizes of 100 mm and 150 mm cubes, as well as 100 mm and 150 mm diameter cylinders.

Brick platen set with spherical seating of size 300 mm x 300 mm, specifically designed for a 2000 kN compression testing machine.

Reviews

There are no reviews yet.