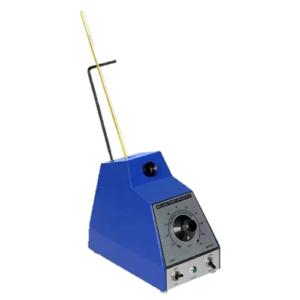

MUFFLE FURNACE

MAKE DINESH SCIENTIFIC

PRODUCT DESCRIPTION:

A muffle furnace is a specific kind of furnace used mostly in industrial and laboratory settings for high-temperature applications. A chamber inside the furnace that keeps the sample or material away from the heating components is referred to as a “muffle”. Its precise temperature control and contamination prevention feature make it ideal for a wide range of industrial and scientific applications.

CONSTRUCTION:

- A particular type of furnace called a muffle furnace is mostly utilized for high-temperature applications in industrial and laboratory environments. The term “muffle” refers to a compartment inside the furnace that keeps the material or sample away from the heating components. It is perfect for a variety of industrial and scientific applications because to its accurate temperature control and contamination prevention feature.

HEATING ELEMENTS:

- Muffle furnaces use heating elements such as resistance wire or graphite rods that surround the muffle chamber. These elements generate and distribute heat evenly throughout the chamber, allowing for precise temperature control.

TEMPERATURE CONTROL:

- Muffle furnaces can reach temperatures that are quite high, frequently above one thousand degrees Celsius. They have temperature control systems built in, allowing users to preset and keep particular temperatures for various uses.

INSULATION:

- Muffle furnaces are well-insulated to increase energy efficiency and maintain a constant interior temperature. Insulating materials guarantee that the furnace runs effectively and assist avoid heat loss.

APPLICATIONS:

- Applications for muffle furnaces can be found in metallurgy, geology, chemistry, and materials science. They are frequently employed in processes like sample heat treatment, annealing, sintering, and ashing.

VERSATILITY:

- Additional features like digital displays, customizable temperature profiles, and safety measures like over-temperature prevention may be available with muffle furnaces, depending on the particular type.

SAMPLE CONTAINMENT:

- The sample is kept in a controlled environment by the inner chamber, or muffle, which shields it from outside influences and avoids cross-contamination. This is especially crucial in analytical and research environments where purity and precision are essential.

- In conclusion, a muffle furnace is an advanced heating apparatus made for uses that need for exact temperature control and high temperatures. Because of its distinctive design and functionality, it is a vital instrument for quality assurance, scientific research, and a variety of industrial processes.

OTHER FEATURES:

- Type K thermocouple

- The chamber has two open coil heating sources mounted on its sides.

- The door opens 180 degrees for convenient access.

- Ceramic insulation that is thermally efficient surrounding the chamber.

- A diameter opening to allow for independent temperature monitoring at the back of the chamber.

- A built-in timer is required.

- A clause allowing for the addition of a ceramic shelf.

TECHNICAL DETAILS:

MODEL |

DS-MF-42-1400 |

| Temperature Stability | ± 1°C at 1000 °C |

| Temperature Uniformity | ± 5°C at 1000 °C |

| Maximum Temperature | 1200 °C |

| Operating Range | 100 °C to 1200 °C |

| Working Volume | 5 L |

| Inner Dimensions (D x W x H) | 25-30 cm x 18-20 cm x 12-15 cm |

| Exterior Dimensions (D x W x H) | 50-55 cm x 32-34 cm x 48-50 cm |

| TEMPERATURE CONTROLFEATURES | |

| Control Type | Single setpoint control with a digital interface |

| Display | Dual LED display indicating actual temperature and setpoint |

| Protection | Mechanical thermal protection relay system |

| Programmable System | Digital control system capable of storing four programs |

| Communication Interface | Equipped with an RS-232 communications interface |

| DATA MONITORING | |

| Access Ports | Access ports for data monitoring sensors |

| Interface | Data monitoring RS232 data interface by cable |

| SAFETY FEATURES | |

| Over Temperature Alarm | Automatic over temperature alarm system |

| Thermocouple Protection | Thermocouple break protection |

| Sensors | Two PT-100 sensors for sample protection |

| Door Safety | Door open temperature cutoff |

| Exhaust Ports | Built-in vent exhaust ports to eliminate contaminants and moisture |

| Power Consumption | 1500 Watt/hr ±10% |

| Electrical | 220-240 V, 50/60 Hz |

Reviews

There are no reviews yet.