ENVIRONMENTAL STRESS CRACKING RESISTANCE

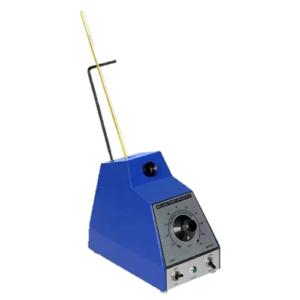

MAKE DINESH SCIENTIFIC

DESCRIPTION:

Environmental Stress Cracking Resistance (ESCR) refers to the ability of a material, especially polymers and plastics, to withstand the initiation and propagation of cracks when subjected to mechanical stress in the presence of specific environmental agents. These agents can include chemicals like detergents, oils, or even prolonged exposure to UV light, which can weaken the material over time.

CHEMICAL INTERACTION SENSITIVITY:

- Materials with high ESCR can resist the damaging effects of chemicals and other stress-inducing agents that might otherwise cause cracking.

STRESS CRACKING RESISTANCE:

- The material’s ability to resist the development of surface cracks or fractures under both tensile (stretching) and compressive (squeezing) stresses.

TEST METHODS:

- ESCR is typically evaluated using standardized tests, such as ASTM D1693 (for polyethylene), where samples are subjected to a constant load in a controlled environment to measure the time to failure.

MATERIAL IMPACT:

- ESCR is highly dependent on the material’s molecular structure, including the type of polymer, degree of crystallinity, and any additives used.

PURPOSE:

- Environmental stress cracking resistance tester (ESCR) is one of the most accurate instruments which used for testing the impact of plastics, rubber and polymers when subjected to extreme environmental factors.

- These samples namely rubber, plastics and polymers react differently to the changing environment.

- It is important for manufacturers to ensure the quality and check the resilience of samples against extreme environmental conditions.

- The instrument provides and simulates the environmental conditions that these samples are subjected to (for Example humidity, chemical fumes, acid fumes and other physical tension) It is an utmost important instrument to check and analyses the physical properties.

- After the completion of the test in the environmental stress cracking resistance tester the sample is then analyzed and studies. Changes in the physical properties are also examined.

- This instrument also helps in improving the efficiency and quality of samples.

TECHNICAL DETAILS:

| MODEL | DS-917 |

| Size of Specimen | 38 mm x 13 mm |

| Size of Test Tube | 165 mm in length, 32 mm in diameter |

| Temperature Range (for water) | From ambient temperature to 90°C |

| Accuracy | ±2°C precision |

| Least Count/Resolution | 0.1°C increment |

| Power | 15A, 220V, single-phase, 50 Hz |

| Heater Capacity | 1-kilowatt |

| Motor Type | Stirring motor |

| Motor Capacity | 1/70 HP, 1350 revolutions per minute |

| Number of Test Stations | 6 stations |

| Body Material | Mild steel with powder coating |

| Display | Digital LED display |

Reviews

There are no reviews yet.