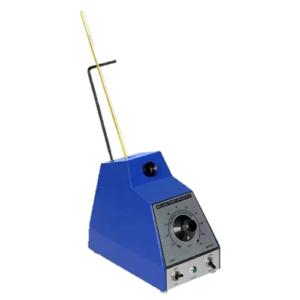

FREEZE DRYER, COLLECTOR COIL, EMAIL ALERT FACILITY, FLASK, DEFROST

MAKE DINESH SCIENTIFIC MODEL DS-LYO-2.5L-50C

PRODUCT DESCRIPTION:

Lyophilizer Freeze Dryer is manufactured in compliance with latest technology using best quality materials and components. Equipped with self temperature adjustable, controllable and detectable functions, our dryer is used for pre- freeze drying process. Bottom of the machine is attached with caster wheels for easy mobility. We offer this Freeze Dryerat market leading prices. The unit has hermetically sealed compressor to maintain temp. Control by electronic digital controller cum indicator with electronic vacuum indicator.

PRINCIPAL OF LYOPHILIZER:

The basic principle in lyophilization is sublimation, in which the conversion from a solid directly into a gas occur. Just like evaporation, sublimation occurs when a molecule gains enough energy to break free from the molecules around it.

PURPOSE OF LYOPHILIZER:

A lyophilized executes a water removal process typically used to preserve perishable materials, to extend shelf life or make the material more convenient for transport. Lyophilizes work by freezing the material, then reducing the pressure and adding heat to allow the frozen water in the material to sublimate.

Suitable voltage stabilizer included.

USES OF LYOPHILIZER:

lyophilized biopharmaceuticals include blockbuster drugs such as etanercept (Enbrel by Amgen), infliximab (Remicade by Janssen Biotech), rituximab, and trastuzumab (Herceptin by Genentech). Freeze-drying is also used in manufacturing of raw materials for pharmaceutical products.

TECHNICAL DATA:

| PARAMETER | VALUE |

| Type | Freeze Dryer, Collector Coil, Email Alert Facility, Flask, Defrost |

| Capacity | An Ice Holding capacity 2.5 Liters of ice before defrosting. |

| Samples | Capable of handling aqueous samples. |

| Footprint | A benchtop with a small footprint. |

| SS Condenser | An upright stainless steel collector coil with SS condenser. |

| Flask | flask that comes with the system and the appropriate adaptors. |

| Rotary Vane Vacuum Pump with displacement capacity | L/min of 90. Absolute vacuum (pressure total): Two x 10-3 gas ballast closed (1.5 x 10-3) Open 5 x 10-2 Gas Ballast (3.75 x 10-2). |

| Vacuum control | · To keep the set point vacuum level

· Use the vacuum control option. |

| Vapors Or Liquid. | The newest moisture detection technology shields system lines from liquids and vapors to stop the vacuum pump. |

| Power Outage | · During a power outage

· the system has a unique setup to stop oil from back-spraying into the collecting chamber. |

| Touch screen | · A color touch screen display with operating settings

· Alert messages and setup parameters · Vacuum level, and optional sample endpoint detection. |

| Facility | A facility for an Email alert about the sample. |

| Voltage supply | · The system has an inbuilt function that protects against power cuts and failures.

· It also has an audible and visual alarm system for alert conditions like power failure · An auto-emailer that notifies the user of any abnormal events during freeze-drying · Improper line voltage supply, etc. |

| Data | Data logging facilities store and present data in tabular or chart form. |

| USB Port | The system has an Ethernet connection built in and a USB port for data transfer. |

| Material | · Stainless steel drying manifold with ten ports

· Complete with valves · Adapters, and other components, to connect flasks of various sizes. |

| HCFC/CFC-free | A single 1/3 horsepower refrigeration system free of HCFC and CFC could cool the collector to -50°C or lower. |

| Hot gas | Auto-shutoff feature for hot gas defrost at +55°C or +60°C |

Reviews

There are no reviews yet.