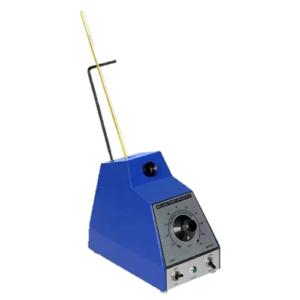

Digital Micro Vickers Hardness Tester

MAKE DINESH SCIENTIFIC MODEL DS-MVHT-10

PRODUCT DESCRIPTION

Digital Micro Vickers hardness tester adopts unique precision design of optics, mechanic and electrics features, make the indentation image clearer, and get more precise measurements. With digital measuring eyepiece, no need for checking the table or inputting the diagonal of the indentation, it can directly shows the test mode, test force, indentation length, dwell time, test numbers, conversion scale, date and time.

PRINCIPAL OF VICKERS HARDNESS TESTER:

The basic principle, as with all common measures of hardness, is to observe a material’s ability to resist plastic deformation from a standard source. The Vickers test can be used for all metals and has one of the widest scales among hardness tests. Principle of any hardness test method is forcing an indenter into the sample surface followed by measuring dimensions of the indentation (depth or actual surface area of the indentation).

| SAILENT FEATURES

Ø Top in work Ø High strength Ø Easy to use |

SCOPE OF APPLICATIONS:

Hardness tester has such function as: automatic hardness calculation, storage, display, printing of results and conversion of hardness value to different scales. This machine can be used as metallographic microscope tissue.

THREE MAIN TYPES OF HARDNESS:

There are three main types of hardness measurements: scratch, indentation, and rebound. Within each of these classes of measurement there are individual measurement scales.

USES OF VICKERS HARDNESS TESTER:

Hardness is the property of a material that allows it to resist permanent distortion, penetration, indentation, and scratching. Therefore, hardness is important from an engineering point of view because resistance to wear by either friction or erosion from steam, oil, and water generally increases with hardness

MATERIAL OF HARDNESS TESTER:

Hardness is the resistance of a material to localised plastic deformation. Hardness ranges from super hard materials such as diamond, boron-carbide to other ceramics and hard metals to soft metals and down to plastics and soft tissues.

DEGREE OF HARDNESS TESTER:

Degree of hardness is defined as the number of parts of calcium carbonate or equivalent to various calcium and magnesium salts present in a million parts of water by mass. It is expressed in ppm.

PROPERTIES OF HARDNESS TESTER:

Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and super hard materials, which can be contrasted with soft matter.

SPECIFICATION:

| PARAMETERS | VALUES |

| MAKE | DINESH SCIENTIFIC |

| MODEL | DS-MVHT-10 |

| MATERIAL | METAL |

| BODY COLOR | WHITE |

| INDENTERS | VICKERS |

| LIGHT SOURCE | LED COLD LIGHT SOURCE |

| Scale | HV0.01 |

| TEST MODE | HV |

| HARDNESS, HV | 2900 |

| Data Output | Inside Printer |

| Conversion Scale | HRA, HRB, HRC}HRD, HRF, HBW, H15N, H30N, H45N, H15T, H30T, H45T, HK |

| MOVING RESOLUTION RATIO | 0.01mm Analogue(Digital optional ) |

| Type of digital Vickers hardness tester | Fully Automatic |

| Max. Height of test sample | 100 millimeter |

| Max. Depth of test sample | 120 millimeter |

| POWER SUPPLY | AC 220V, 50-60HZ |

| OPERATING AIR TEMPRATURE | 0-40 |

| X-Y TESTING MOVING RANGE | 25x25mm |

| Optional accessories | Image analysis software |

| Dwell time | 0-60 sec |

| Magnification of microscope | 100x,400x max. |

| Testing force | 1000gf Min, 10gf Testing Force: 10gf (0.098N), 25gf (0.245N), 50gf (0.49N), 100gf (0.98N), 200gf (1.96N), 300gf (2.94N), 500gf(4.9N), 1kgf (9.8N) |

| X-Y TESTING table dimension | 100x100mm |

| total magnification of microscope | 100x(for observation) |

| Min. Measuring Unit | 0.01 micrometer |

| Testing Force | 10gf (0.098N) |

| Operating Air Pressure, kPa | 94 106.7 |

| Operating Humidity | Up to 65 percent |

| Frequency | 50-60 Hz |

| Control Panel | Touch Screen |

| DIMENSION | |

| Length | 535 millimeter |

| Weight | 50 kilogram |

| Height | 600 millimeter |

| Width | 235 millimeter |

ADDITIONAL ACCESSORIES:

Indentation measurement using both auto and manual measurement mode. Automatic calibration using hardness block Hardness tester with image analysis software for automatic measurements.

STANDARD ACCESSORIES:

10X Digital Micro Eyepiece, 10X & 40X Objectives, Vickers Indenter, X-Y Testing Table, Flat Fixture, Thin Fixture, Small Parts Fixture, Level Bubble Vail, Power Cable, Dust-Proof Cover, Instruction Book, Warranty Card, Accessory Case 2 Pieces, Standard Block of Hardness 4 Pieces, Horizontal Adjusting Screw, Axle weight, Test Block ( Middle and high range), Regulating screw

Reviews

There are no reviews yet.